Inventory Management

Inventory management is crucial to a business's profitability, but many small businesses don't have good management practices in place.

This means money on the table, and friends, it’s time to pick it on up!

Here I'll be sharing the methods we use within both Bailey's Blossoms and Peyton Bre. We're going to break this down into three main parts.

- Understanding your on-hand stock. What to do when it goes stale and how and when to mark it down.

- Purchasing new inventory. Taking into account seasonal trends and making better projections and purchase smarter.

- Organizing your inventory. Create efficiencies in your workplace that will save you time and money.

As a new business owner, I didn't understand that inventory in many ways is seen as cash in the bank. At the end of our first year in business, I intentionally spent any excess funds on additional inventory for the new year (thinking that that would make me net zero and save me from having to pay obscene amounts of money in taxes). Rookie mistake! Your inventory should be viewed as a bank of sorts, but instead of cash you have product, and based on the time of sale, the exchange rate you can cash it in for will be higher or lower.

Obviously the goal is always to get the highest return as you sell off your product. When it comes time to do your taxes, inventory is not actually a write off. You can't write off the inventory that you have on hand, but rather the inventory that you have sold using the COGS or “cost of goods sold”. For example, if you have an item that you purchased for $5 which you sold for $10 your cost of goods sold would be 50% f the sale price which was $5. Now full disclaimer, taxes are absolutely not my forte and unless they're yours, I would suggest consulting with a tax advisor for specifics pertaining to your business and additional information on what you can and can't write off.

The way we manage our assets and specifically inventory has a direct impact on our profitability.

If you purchase too much, you tie up your liquid funds that could be used for other expenditures. This can slow down your inventory turns and overall growth and may cause you to heavily discount later on. An inventory turn is the cycle in which you rotate out all of your inventory and replace it with new inventory.The better your inventory management, the more turns you'll have throughout the year. On the flip side, if you purchase too few, you have an opportunity cost lost where you sell out prematurely and prior to restocking have lost potential sales and customers who would have purchased the item had it been available.

If you've ever felt like you were guessing or taking a gamble when ordering your inventory, you're not alone! I don't know a single company out there that wouldn't benefit from having a magic eight ball that can predict the future. But the good news is there are some tricks of the trade that can help you make better projections.

Managing your inventory is more about making informed decisions than it is about taking a gamble on the future.

It's analyzing what your current trends are against your current growth rate so you can project what you will sell in advance of selling it.

First, on-hand inventory..

This past school year, I was invited to be in charge of spirit wear at my kid's middle school. I went into the first meeting and was told what my budget would be for spirit wear that year. I began to ask questions about our past sales history. Challenge number one was that those previously in charge of spirit wear had never broken down the sales. I didn't know which sizes sold best or at what point we became profitable. As I asked questions, I realized the school had never been profitable on spirit wear for as long as anyone could remember, but I also understood that that could easily be changed. In previous years we had always spent the budget that we had for spirit wear, but we had never spent it based off of what our needs were.The first thing I had to do was do a full inventory checkup on what we had on hand. I went to the school and I pulled out all the old styles from years past. I organized them by style I broke them up by size. I quickly determined that we had more in backstock than we were projected to sell that year in total. In order to find out what had been sold previously, I counted up all the stock and deducted it from the purchase orders that had been made the previous year. In that way, I was able to see exactly what sizes were selling the most, so we could better project what we could expect to sell moving into the new year. We only needed a few filler sizes and spent a fraction of the budget given. The remaining budget was able to be reallocated to provide value in another departments, and for the first time, spirit wear became profitable!

This holds a lot of parallels into our own businesses. If we're not tracking things, we have no eyes moving forward.You cannot do smart business without being able to clearly project what you can expect. The more we see behind us, the more clearly we can project that things that are going to happen in front of us.

Each industry has seasonal trends. In the fashion industry, the seasons and weather are the main drivers of the trends we see. For example, there are spring and summer color palettes and fall and winter color palettes. What is selling is always about a step or two ahead of what you might expect. We all know the fall months within the US are September, October, November, but if you're trying to sell fall items in November, you're going to have a really hard time doing so. The transition to selling fall items actually occurs in July with full-fledged fall sales happening in August and September and the transition to winter begins in October and by the time November comes around, you should be in full-fledged winter mode.

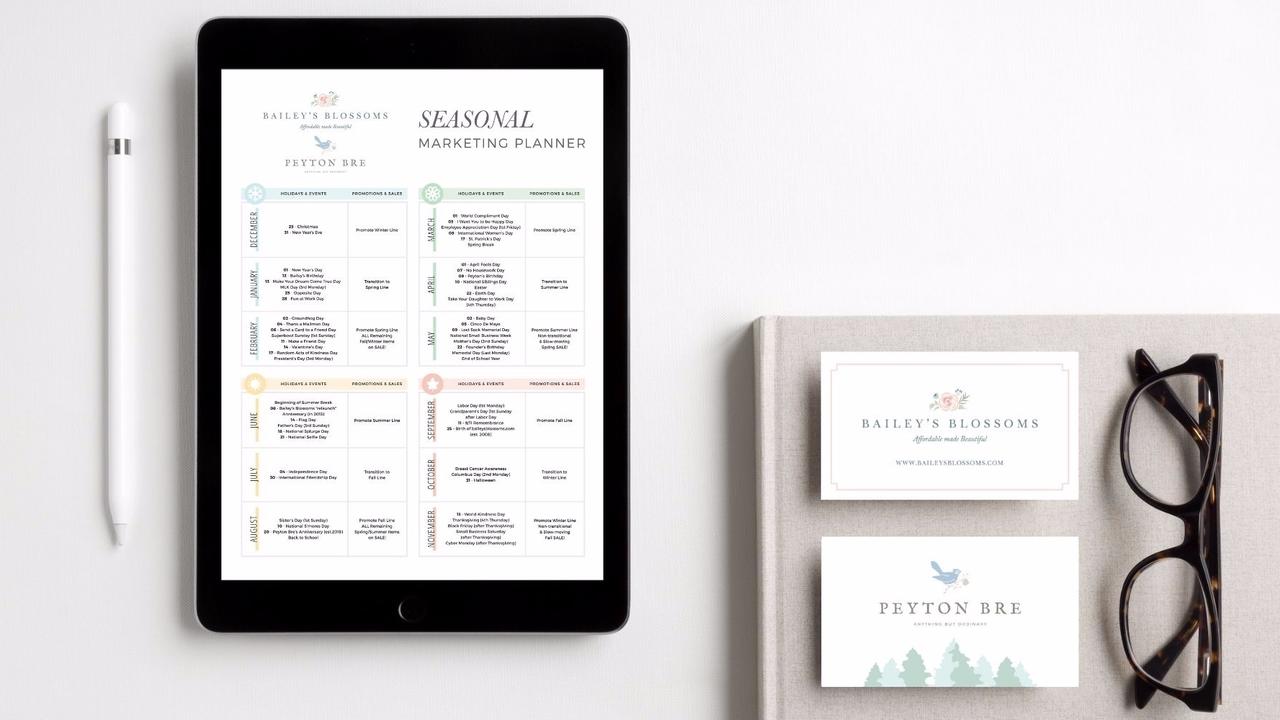

Let’s break that down shall we? Here is an example seasonal marketing calendar that we use for Bailey's Blossoms & Peyton Bre. You can download it for FREE by clicking here.

The trend in the fashion industry is about two months ahead. It's vital to understand the seasonal transitions in your industry in order to stay ahead of the game and not feel like you're constantly playing catch up all the time, wondering why items that you think should be selling right now, your competitors are already putting on sale.

TAKEAWAY #1: Map out your seasonal calendar. Clearly mark your transitional months and take into account major holidays. Then you can determine general rules such as transitional months where old inventory is marked down and when last season's inventory needs to be completely gone. Understanding this helps me understand how to get the highest exchange rate, so to speak, for my inventory. If I wait too long to discount, the discount becomes much more extreme and that can be a recipe for disaster. When it comes to inventory, it is vital to be one step ahead. As a general rule, about 80% of your profits come from about 20% of your inventory, so the items that fall into that 20% should be at the top of your priority list and the last items to be discounted.

The closer you are to the next season, the higher the discount is going to be in order to sell the past seasons items. So as long as you're on top of things, the likelihood of your profit margin being higher is increased. Once you get your current inventory on a calendar rotation and markdown sale schedule, purchasing your new inventory becomes much easier!

With a year or two of business under your belt, it's easy to pull last season's data to determine what types of items you sold the most, so you can better project based off of your growth rate, how much you’ll need. For example: Let’s say that you sell four types of items; rompers, dresses, tops and bottoms. In the spring season, rompers make up 50% of your sales, dresses take up 25%, tops take up 15%, and bottoms are the remaining 10% of your sales. Your cost of goods sold is 50% when you sell at full price and you sold $20,000 last April. In order to maintain the same sales volume, you would need to spend $10,000 on inventory expecting to sell 100% of the inventory you purchased. Now 50% of that budget would go towards purchasing rompers, 25% towards dresses, 15% towards tops, and 10% towards bottoms. But hopefully your business is not in a standstill and it's growing and if this is the case and you've seen a 20% growth over last year, then you would need to take that $10,000 inventory budget from the previous year and turn it into $12,000 which is a 20% increase in budget. Now obviously this math I'm doing is very simplistic and I’m also basing it off of the assumption that you're going to sell 100% of your inventory, which is rarely (if ever) the case. It's important to constantly monitor your inventory levels and have a solid rotation of new arrivals and replenishments coming in to fill the vacancies your sales have created. How often you need to purchase will vary based on the processing and delivery time of those you purchase from.

Another way to project your inventory needs if you don't have sales data from previous years would be to look at your traffic. If you're in the realm of online sales then your website analytics should give you a basic conversion rate. In this way, you can work backwards and determine based off of the sales goals you have, how much traffic you need to drive to your site in order to get the appropriate amount of conversions needed to sell the amount of items you are planning to purchase. For example, if I know that my average order value is $50, and I have a 2% conversion rate on my site, meaning two out of every 100 visitors to my site, complete a purchase, I can work backwards to get to my monthly sales goal. Let's say my goal is $20,000, that equates to roughly 400 orders at $50 a piece and I'll need approximately 2000 visitors to my site to convert those 400 customers. The same inventory needs would apply. If I can maintain that degree of traffic, I can project that my sales will indeed be around $20,000 by the end of the month as long as I had the seasonally relevant inventory on hand to sustain it. Make sense?

Understanding your inventory needs based off of your sales projections is great, but this needs to be done well in advance of the month itself. In order to ensure that you have the proper seasonal inventory on hand before that given season comes around, you need to mark on your calendar the turnaround time in order for it to get to you. This way you can ensure that you can sell your inventory within the optimal time without being forced to discount it.

Nothing has the power to set a company back faster than an unreliable supplier who can't deliver on time.

When you choose a brand or supplier, you need to also understand their production and delivery times. If you purchase a particular item which sells out three times faster than your original projections had predicted, how quickly can you restock it before selling out completely and losing that momentum? Within the fashion industry, there will always be a degree of unknown as much of the sales are based on popular opinion. The closest you can get to clear projections are general seasonal styles and colors that you've had success with previously or see gaining momentum in the general market. Social media is great for providing insights on these trends as long as you understand that most consumers are unwilling to wait an excess amount of time from initial concept to delivery. Oftentimes those who would have purchased in the moment if the product were available, will have lost interest by the time the product is finally released. Be cautious of preorders and presales and sneak peeks given to your customers well in advance of your release date.

“Speed to market” means the quickest time that you can get it out to your customers, the quickest time that you can deliver it. The first person who has dresses to sell for Easter is usually going to sell the most dresses for Easter. Likewise, the person who has enough stock to maintain and continue that momentum for those Easter dresses is going to also continue to take and keep hold of that market share.

TAKEAWAY #2: Crunch the data!Determine your cost of goods sold and month over month growth percentage. Look at past sales or traffic data to project your inventory needs for a given month or season, well enough in advance to allow time for production and shipping. If you're working with a brand like Bailey’s Blossoms or Peyton Bre that ships within 2-3 business days, then your need to pre-plan is not quite as heavy. Whereas for us (Bailey’s Blossoms & Peyton Bre), since we manufacture the products, we are actually designing and producing products for winter in the spring, understanding it's going to take about three to four months in order to complete that product and get it to us.

Keeping your inventory organized saves money by creating efficiencies in the order fulfillment and cycle counting process.

For both Bailey's Blossoms and Peyton Bre, we use the Shopify platform to manage our inventory numbers, and Shipping Easy to manage our warehouse and bin locations. The two systems communicate based off of the SKU number, so each variant of size or color within each product has its own unique SKU. We then allocate a location to each variant/SKU. The whole idea behind this is to get all the information out of your head and make your system so easy that you can literally train someone in less than five minutes to do what you or your team members do. Honestly, my kids can come to our warehouse and figure out how to pull an order. It should be THAT easy!

When creating your SKU system, you should be able to in great part identify the product type by your SKU. For example, ours may be G for “girl” RMP for “romper” and 1001 for the first size variant going up to 1010 for the last size variant (understanding that we have a 10-size run).

For product locations, if your garage is your warehouse as mine used to be, it can be as simple as this: There are three rows of racks making up aisles A, B, and C with five sections in each aisle. Each rack has three shelves (1, 2, and 3), and each shelf houses five bins (1, 2, 3, 4 and 5). So, your location could be A3-2-4 which means the product is found on isle A in the third section on the second shelf in bin number four. Another tip and trick for efficiency is organizing the placement of your items to where fast moving and seasonally relevant items are clustered together in order to create less required movement and quicker fulfillment times. If you have a batch of products that you know 80% of your orders is going to contain, keep those front and center. This way they can be easily pulled together with little or no walking through your space. The items that are slower moving should be placed in locations that are the furthest away, understanding that you won't be navigating to them as often.

Now, periodically you should be performing cycle counts and this means you go down a specific aisle and count the products to ensure the inventory numbers in the system match your on hand quantity. A few things that could throw these numbers off would be customer returns and exchanges as well as damaged items that you need to remove from your inventory. All of these items can and should be reconciled on a maintained and regular basis. As you replenish your inventory, also create a method to ensure that the items that come first in are the ones that are shipped out first as well. This ensures you don't have any expiring inventory due to it being buried at the bottom of a pile.

Are you still with me?? We've gone over a LOT and hopefully you'll be saving this and going back to it time and time again to reference all of these points because there is a lot here, but a couple of questions that I want you to consider:

What is the current life cycle of your customers?

When do you want to acquire a new customer and how often do you want them to reorder? For Bailey's Blossoms, we want to acquire a new customer in the infancy stage, so we have that customer for about five years, at which time we would hope to transfer them to our older girl’s line, Peyton Bre. Now our goal is for our customers to purchase with us on a quarterly basis, so we want four full inventory turns or rotations throughout the year at minimum to coincide with each season. Consider if you went to your favorite store and you walked in this month and you loved it and the next month you go and the exact same items are up, with the exact same setup is up. You probably aren’t doing much walking around again. There's a reason that websites change so frequently, and that brick and mortar locations change so frequently too.

Everybody needs to constantly feel like they're experiencing something new and that heavily revolves around how quickly we are able to turn or rotate our inventory in and out.

The more rotations you have, the more effectively you can retarget your existing and past customer base. When looking to grow your business and increase your inventory turns, there are two main options. You can either sell more to your current customers or find more customers. Attempting to sell the same inventory to the same group of people will eventually exhaust and frustrate them, causing them to potentially disengage with your social groups and other contact lists. The key is the size of your pool of options. For smaller audiences and fan bases, you'll want to purchase smaller quantities of each item and a larger variety of items. In order to sell more of the same item, you need a larger amount of people to market them to.

What are the key takeaways?

- Inventory management saves money.

- First in, first out keeps inventory from expiring. It means that your oldest stock first in gets sold first, first out, not your newest stock. Now obviously that is attributed to items that you are restocking on a continual basis. Those are your staple items, those items that year-round have relevancy and you're not looking to get rid of.

- Set minimum inventory levels for staple items that trigger a reorder. The minimum should be set based on how quickly the item sells in comparison to how long it takes to receive a new shipment to you.

- Avoid dead stock from seasonally irrelevant items that you can no longer move by discounting them in the appropriate season.

- Inventory management helps you manage your storage space. Storage space is limited so this is vital unless you want to pay increased rental fees by constantly expanding your space. It also helps free up liquid funds that could be used to scale your company in other ways such as marketing or personnel.

- On hand inventory affects sales by determining how much you can sell while inventory needs effect expenses by determining and even limiting what you have and can afford to buy. This all comes down to how much cash you have on hand and unless you have investors providing a steady stream of cash to you, cash is king! You can only get so far without it.

Always remember:

Improved inventory management equals improved cashflow. Money spent on inventory is money not spent on other areas that could fuel your growth.